23 Dec Jean Paul Gaultier – Christmas Tree Boxes

In December we were tasked by our client – Us Experiential to construct and deliver 8 Christmas Tree Reveal Boxes for their client Jean Paul Gaultier. Here at Colourpoint we are quite used to being challenged by our clients, so this sounded easy enough?

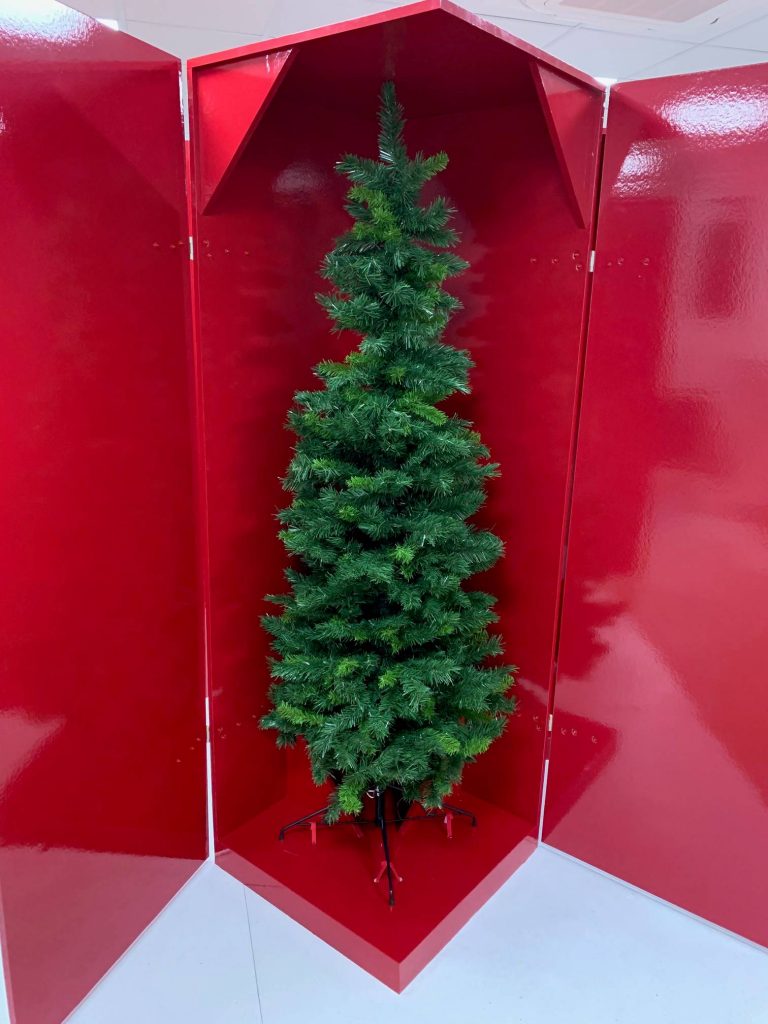

And a challenge this certainly was. The Tree Reveal Boxes were designed to house a 6 foot tall artificial Christmas tree and stand. The idea was to build a box similar in style to an old telephone box but with a double door that would allow the box to open fully on two sides thus enhancing the overall impact of the big reveal.

To start with, our team of box engineers had to work out all the dimensions, draw up templates and then make a prototype but at the 10th of the size. Once a few tweaks had been made and our client was happy it was on to stage 2 – a full scale working prototype.

We used 10mm Reboard, this is a very strong and durable product used for exhibition stands. This was CAD cut and bevel cut on our ZUND to size and shape, then mounted and wrapped throughout. For the inner and outer material we were asked to colour match a red perfume bottle, so we printed this on our Anapurna UV large format printer directly onto a white gloss vinyl and then applied it to the Reboard.

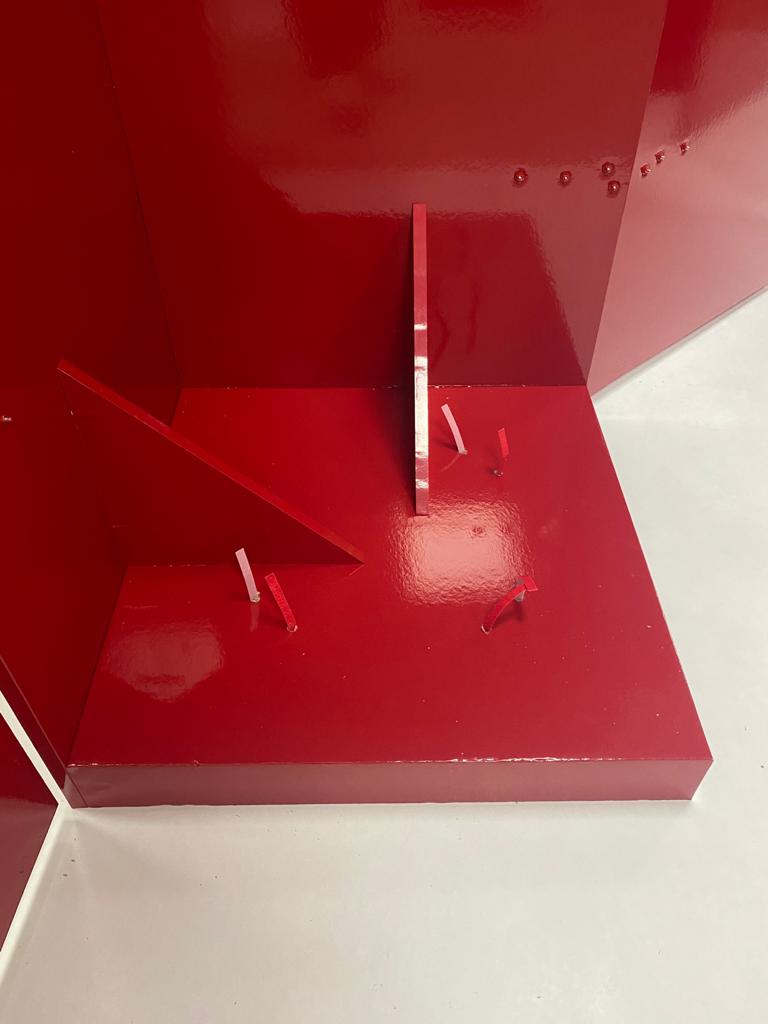

Once the first prototype was made up, we discovered there was an issue with the structural integrity of the roof towards the front, due to lack of support. This reinforces the reason as to why we produce prototypes as it allow us to pinpoint any such issues and address them immediately. So we engineered a couple of support struts from the Reboard, wrapped and then fitted them, which solved the problem. Then to hold the tree in place we made three slits in the base and fed through 3 strips of red Velcro to secure the tree footings. Each box had two hinged doors either side, which were sprayed gold, that butted up to one another and finished flush.

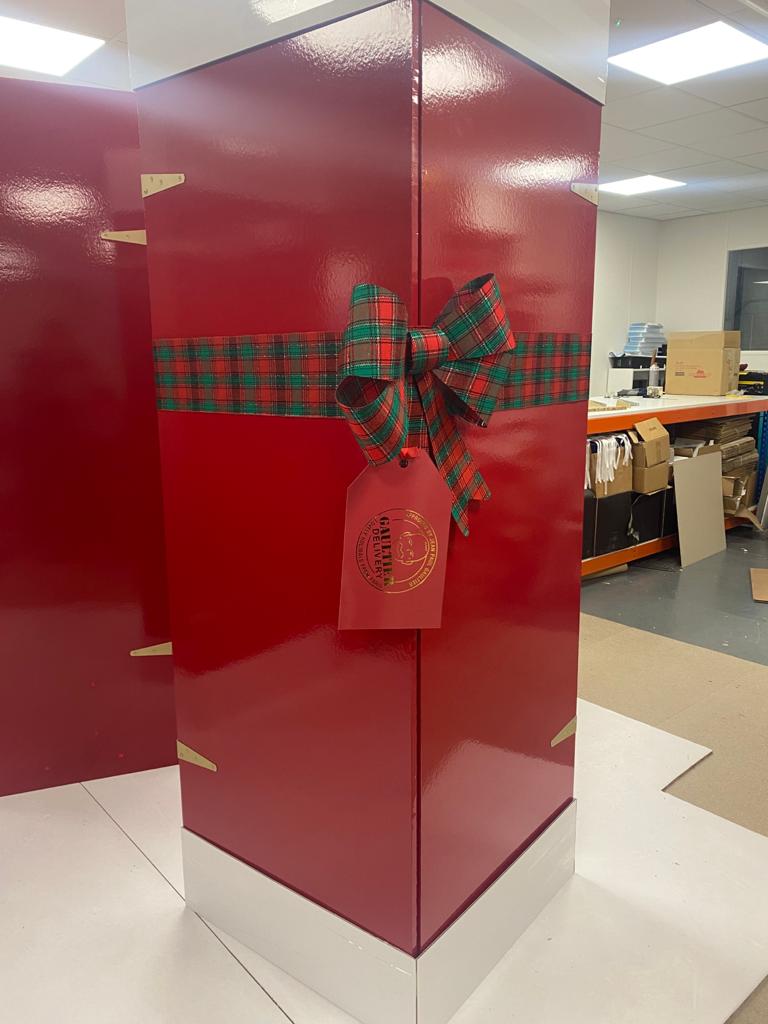

Due to time constraints and quick turnaround on the delivery of this product, sign off was done via photographs and email, and once we had the thumbs up, we were on to producing the remaining 7 Boxes!

A total of 32 hinges and 544 screws were used for the production of the 8 boxes. All of the internal screws were sprayed red to blend with the background.

Our team of Elves worked tirelessly over the whole weekend and more to ensure that these were delivered to the highest specification and on time.

For transportation purposes we also made a protective casing for the top and bottom of the box which was made from a white ‘e’ flute carton board.

The project was turned around in approximately 50 hours from start to finish and the Boxes were delivered on time to a very satisfied customer, who then added a fully decorated tree, LED lights and presents around the base of the tree and finished it off with a beautiful tartan ribbon, bow and a tag saying “pull me” which once pulled opened the doors open to reveal the beautifully decorated tree.

First of all, a huge thank you to US Experiential for entrusting us with this great project, and also a massive thank you to the team at Colourpoint who worked around the clock to make this happen.

We are Colourpoint – It’s what we do!

To see the Us Experiential LinkedIn video on the delivery of the boxes – click here.

Sorry, the comment form is closed at this time.